VICWA® Para Aramid Pulp

Previous

Next

100% para aramid pulp for friction and sealing application

VICWA® para-aramid pulp is widely used in friction and sealing field, significantly increasing its performance and service life.

VICWA® Para-aramid pulp is made from VICWA® filament yarn whose composition is poly (para-phenylene terephthalamide). After a series process of cutting, grinding and suspending in water, the fiber is fibrillated into pulp. The pulp not only inherits the high-strength, high-modulus, high-temperature resistance, abrasion resistance and excellent chemical stability from para-aramid fiber, but also has high dispersibility, specific surface area and grip force to provide reinforcement and viscosity control under shear stress.

Features:

- High strength-to-weight ratio

- Heat and chemical resistance

- Flame retardant and fireproofing

- Cut resistance and electrical insulation

Main Applications:

- Gasket seal

- Clutch plate

- Brake pad

- Wear-resisting

Storage:

VICWA® para-aramid pulp should be kept dry in original bags and properly stocked.

Preferably store at room temperature with 35-65% relative humidity.

Avoid the sun, rain and fire.

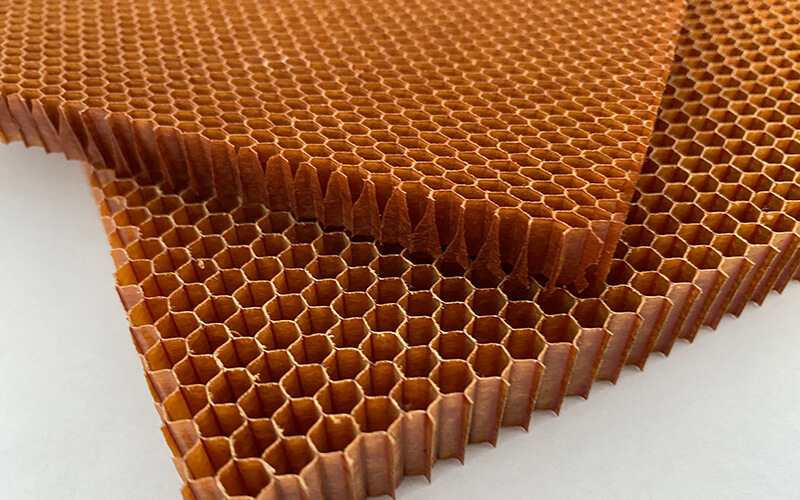

Para Aramid Pulp Application:

Packaging:

Net weight:

5kg per bag

27 bags (135kg) per pallet

Shipment And Transportation:

Shipment by sea: Generally 20 pallets can be loaded into 20 feet container with total net weight of 6,900kg.